Our profession is the technical research and development

KOGÁT Public Benefit Nonprofit Ltd is basically a company engaged in technical research and development. The main aim of the company is to serve effectively the scientific-technical research and development needs arising in Hungary and abroad, mainly in multidisciplinary fields. Our goal is furthermore to systematize the practical and theoretical information achieved in our fields of expertise, collect them in a database and disseminate them in the framework of education, consultations, exercises.

We undertake the analysis and implementation of innovation needs arising in the following areas, primarily based on explosive material processing technologies:

Our profession is the technical research and development

KOGÁT Public Benefit Nonprofit Ltd is basically a company engaged in technical research and development. The main aim of the company is to serve effectively the scientific-technical research and development needs arising in Hungary and abroad, mainly in multidisciplinary fields. Our goal is furthermore to systematize the practical and theoretical information achieved in our fields of expertise, collect them in a database and disseminate them in the framework of education, consultations, exercises.

We undertake the analysis and implementation of innovation needs arising in the following areas, primarily based on explosive material processing technologies:

Energy efficiency

- Reduction of losses on electrical networks by eliminating contact corrosion

- High efficiency heat exchangers

- Superconducting joints

Special technical material compositions

- Compaction of metal and ceramic powders

- Production of multi-layer metal materials

Environmental protection

- Remediation: in situ reduction of hydrocarbon contamination of soils

- Education and consultations

Why is it beneficial for you to work with us?

Thanks to our well established scientific-technical connections to universities, research institutes and companies, we are able to undertake the implementation of innovation needs and tasks that arise from our partners and clients, so we can find the necessary expertise and infrastructure beyond our own capabilities.

Flexibility

We are a small and flexible company that can solve a wide range of special technological needs

Extensive experience

Our colleagues have practice and experience in different technical fields for a long time

Own infrastructure

Hungary’s only civilian-owned explosive chamber is owned by our company

General goals of our company

- Creation, continuous development and operation of an environmental protection data bank (Content of the data bank: environmental protection technical problems and the technologies aimed at solving them)

- Integrating the needs and opportunities of civil and military institutions related to environmental protection

- Carrying out technical research and development activities, focusing on solving the problems identified during the activities specified in the previous points.

- Dissemination of knowledge by organizing workshops, courses, professional presentations and demonstrations

We undertake:

- literature and market research,

- basic research / preliminary development,

- prototype production / demonstration / experimental (pre-competitive) development

- industrial or applied research

- fulfillment in the above-mentioned topics, as well as on the basis of specially arising needs.

Our activities

Bonding technologies – Superconductors

High-quality metallic bonding of aluminum and copper-sheathed superconducting cables

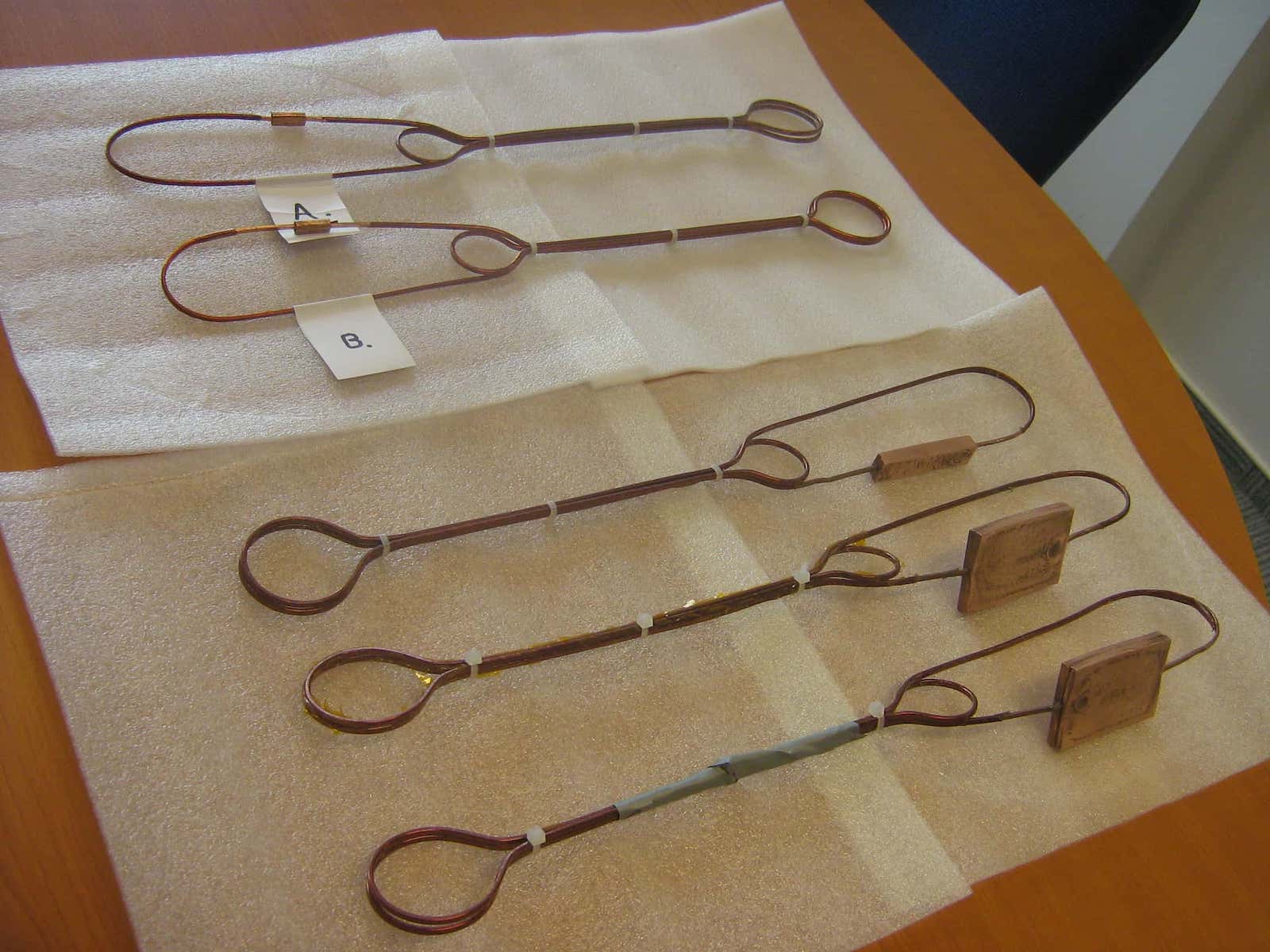

Bonding technologies – Wire rope

Development of in situ bonding technologies for steel ropes and electrical transmission lines

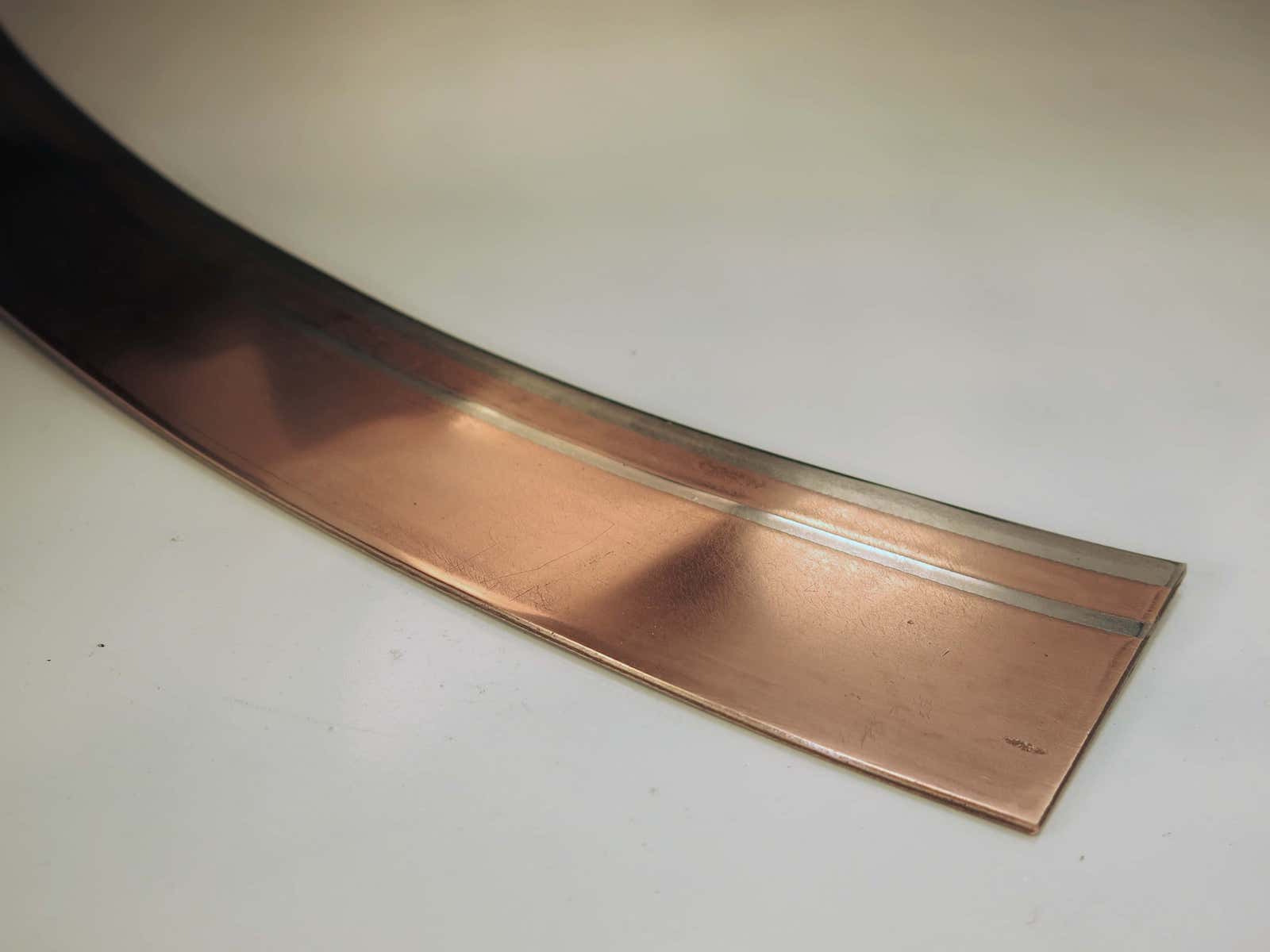

Cladding – Multilayer metals

Production of copper-aluminum, steel-aluminum and steel-copper bimetals by explosive cladding

Tube forming

Production of metal tubes with an optimized shape for the production of high-efficiency heat exchangers using explosive technology

Conductors with ceramic insulation

Production and development of electric conductors with ceramic insulation

Explosion chamber

Operation of an explosion chamber for technical R&D works of institutions

Education and training

Development of teaching materials and curriculas for students of technical universities and high schools about the HERF (High Energy Rate Formings) technologies Consultations (Diplomatic plans, doctoral thesis)

Organization of technological demonstrations for engineers working on the field

Publications of our colleagues

- Andras Szalay, Athanasios G. Mamalis, Istvan Zador, Toshiaki Hasebe, Jozsef Janik: Manufacture of experimental control rods by explosive powder compaction,In: ESHP 2019, Conference on Explosion Shock Waves and High Strain Rate Phenomena, Puducherry, India 19-21 March, 2019.

- Szalay András, Zádor István, Horváth Dániel: Ivó-, öntöző-, itató és termálvizek kezelése speciális hazai gyártású adszorbensekkel,In: Mikroszennyezők a vízben – okok, kritériumok és megoldások Szakmai Nap, Budapest, 2019. április 17. (MaSzeSz).

- Bozo Dalmacija, Andras Szalay, Daniel Horvath, Istvan Zador, Snezana Maltic, Aleksandra Tubic, Jasmina Agbaba: Pilot scale investigation of arsenic removal from water by newly synthesised adsorbent,WATER AND SANITARY TECHNOLOGY XLVI : 2 pp. 61-67. Paper: UDK: 628.139:546.29 , 7 p. (2016).

- Szalay András, Zádor István, Göbl Nándor: A reaktortechnikában alkalmazott különleges többkomponenses anyagok készítése robbantásos fémmegmunkálással, In: Magyar, Robbantástechnikai Egyesület (szerk.) 13. Fúrás- robbantástechnikai nemzetközi konferencia-2016 Budapest, Magyarország (2016).

- Andras Szalay, Istvan Zador, Jozsef Janik: 4th Design and Engineering of Neutron Instruments Meeting Budapest, Magyarország (2015).

- Andras Szalay; Athanasios G. Mamalis, Achilleas K. Vortselas, Istvan Zador, Laszlo Lukacs: Reduction of the contact corrosion on the electrical networks by applying bimetallics,MATERIALS SCIENCE FORUM 792 pp. 153-158. , 6 p. (2014).

- A. Szalay, A. G. Mamalis, I. Zádor, A. K. Vortselas, L. Lukács: Explosive Metalworking: Experimental and Numerical Modeling Aspects,MATERIALS SCIENCE FORUM 767 pp. 138-143. , 6 p. (2014) ISBN: 9783037858264.

- Horváth, Eszter; Török, Ádám; Ficzere, Péter; Zádor, István; Rácz, Pál: Optimisation of Computer-aided Screen Printing Design,ACTA POLYTECHNICA HUNGARICA 11 : 8 pp. 29-44. , 16 p. (2014).

- István Zádor, Ádám Török, Pál Rácz, Istvan Vajda: Green Energy from road vehicle shock absorber,MATERIALS SCIENCE FORUM 792 pp. 287-292. , 6 p. (2014).

- Lukács László, Szalay András, Zádor István: Robbantással készített drótkötél hurok,MŰSZAKI KATONAI KÖZLÖNY 23: 3 pp. 75-88. , 14 p. (2014).

- Lukács László, Szalay András, Zádor István: Robbantással készített drótkötél hurok,In: Bohus, Géza (szerk.) “12. Fúrás-robbantástechnika 2014” Nemzetközi Konferenca kiadványa Budapest, Magyarország : Magyar Robbantástechnikai Egyesület, (2014) pp. 49-60.

- András Szalay, A. G. Mamalis, István Zádor, A. Votrselas, László Lukács: Explosive metalworking: Experimental and numerical modeling aspects, MATERIALS SCIENCE FORUM 767 pp. 138-143. Paper: Explosive metalworking:Experimental and numerical modeling aspects , 6 p. (2013).

- A. Szalay, L. Lukács, I. Zádor: Bonding Of Steel Ropes by Explosive, In: Krivanek, Vaclav; Stefek, Aleksandr (ed.) International Conference on Military Technologies : ICMT 2013 Brno, Csehország : University of Defence, (2013) Paper: 32.

- A. Szalay, L. Lukács, I. Zádor: Explosive metalworking technologies,In: 8th Nordmetall Colloquium Chemnitz, Németország (2013) Paper: 06.

- Dr. Zádor, István; Dr. Ádám, Török; Dr. Rácz, Pál; Dr. Vajda, István: Green energy from road vehicle shock absorber,In: Eight Japanese-Mediterranean Workshop on Applied Electromagnetic Engineering for Magnetic Athens, Görögország (2013) Paper: 45.

- Pavel Manas; Szalay, András; Zádor, István; Lukács, László: Fabrication of formed metal tubes for heat exchangers by explosive technologyIn: Krivanek, Vaclav; Stefek, Aleksandr (szerk.) International Conference on Military Technologies : ICMT 2013 Brno, Csehország : University of Defence, (2013) pp. 353-360.

- P. Manas, A. Szalay, I. Zádor, L. Lukács: Fabrication Of Formed Metal Tubes For Heat,Paper: 45 In: Krivanek, Vaclav; Stefek, Aleksandr (szerk.) International Conference on Military Technologies : ICMT 2013 Brno, Csehország : University of Defence, (2013).

- Szalay, András; A. G. Mamalis; A. K. Vortselas; Zádor, István; Lukács, László: Reduction of contact corrosion in electrical networks by applying bimetallicsIn: G. Kladas (ed.) The Eighth Japanese-Mediterranean Workshop On Applied Electromagnetic Engineering For Magnetic, Superconducting, Multifunctional And Nano Materials (JAPMED’8) : Conference Proceeding Athén, Görögország (2013) Paper: JP8-59.

- Dr. Lukács László, Szalay András, Dr. Zádor István: Robbantásos fémalakítás és a repüléstechnikaIn: Szilvássy, László (szerk.) Repüléstudományi Közlemények : “Repüléstudományi Konferencia 2012” című konferencia kiadványa.

- Laczó, Sándor; Horváth, Dániel; Zádor, István: AsMet – Jednoduché riesenie pri obstranovaní arzénu z vody,In: Viliam, Simko (szerk.) Optimalizácia a modernizácia zásobovania pitnou vodou Nový Smokovec, Szlovákia : ENVI-PUR s.r.o., (2012) pp. 139-146.

- Lukács, László; Szalay, András; Zádor, István: Výroba keramických kompozitov pomocou trhacích prác,In: Mikulás, Beranek (szerk.) Trhacia technika 2012 : zborník prednášok z medzinárodnej konferencie Banská Bystrica, Szlovákia : Slovenska spolocnost pre trhacie a vrtacie prace, (2012) pp. 76-81.

- Lukács László, Zádor István, Athanasios G. Mamalis, Szalay András: Fémcsövek alakítása robbantással, növelt hatásfokú hőcserélő készítéséhez,MŰSZAKI KATONAI KÖZLÖNY XXII : külön pp. 128-139.

- Lukács László, Szalay András, Zádor István: Robbantásos fémalakítás és a repüléstechnikaREPÜLÉSTUDOMÁNYI KÖZLEMÉNYEK (1997-TŐL) XXIV : 2 pp. 431-446.

- Lukács László, Szalay András, Zádor István: A repülőgépek gyártásánál alkalmazható két- és háromrétegű fémanyagok előállítása robbantásos plattírozással,REPÜLÉSTUDOMÁNYI KÖZLEMÉNYEK (1997-TŐL) XXIV : 2 pp. 447-459.

- Lukács László, Szalay András, Zádor István: A repülőgépek gyártásánál alkalmazható két- és háromrétegű fémanyagok előállítása robbantásos plattírozással,In: Szilvássy, László (szerk.) Repüléstudományi Közlemények : “Repüléstudományi Konferencia 2012” című konferencia kiadványa

- Zádor István, Athanasios G. Mamalis, Lukács László, Szalay András: Fémcsövek alakítása robbantással, növelt hatásfokú hőcserélő készítéséhez,In: Bohus, Géza (szerk.) A fúrás-robbantástechnika 2012 c. konferencia előadásai Miskolc, Magyarország : OMBKE Robbantástechnikai Szakbizottság, (2012) pp. 153-164.

- Zádor István, Lukács László, Szalay András: Kerámia szigetelésű fémszerelvények készítése robbantásos portömörítéssel,In: Pálinkás, Sándor; Szabó, Gábor; Szűcs, Máté (szerk.) XIV. Képlékenyalakító konferencia : Miskolc 2012.

- István Zádor; Ádám Török; István Vajda; László Palkovics: Oscillation control over light duty cars using magnetic semi-active shock absorbers,TRANSPORT (VILNIUS) 26 : 3 pp. 284-289.

- Zádor, István (ed.); Szalay, András (ed.); Hasebe, Toshiaki (ed.): Compact LHC splice clamp (included shunt) design with rapid cold welding techniqueBudapest, Magyarország

- Kovács, Viktória Barbara; Török, Ádám; Zádor, István: Analysis of waste transport in relation to biogas utilisationIn: Duzynski, Adam; Chlopek, Zdzislaw; Cupial, Karol; Golec, Kazimierz (szerk.) Gas Engine : Silniki gazowe.

- Zádor István, Török Ádám: Személygépjárművek környezetbarátabbá történő átalakításának gazdasági kérdéseipp. 1-5. , 5 p. In: Péter, Tamás (szerk.) Innováció és fenntartható felszíni közlekedés konferencia : IFFK 2010.

- Zádor, István (ed.); Dr. Göbl, Nándor (ed.): Production of non-explosive compressed gas with blind cartridgesBudapest, Magyarország

- Zádor, István; Markovits-Somogyi, Rita; Török, Ádám: INVESTIGATION OF POSSIBLE IMPROVEMENTS OF GREENING THE PRIVATE CARS IN HUNGARY FOCUSING ON ECONOMIC ASPECTSpp. 184-193. In: Stanislaw, Borkowski; Olena, J Shevtsova – mgr, inz Krzysztof Knop (szerk.) Process Innovation

- Zádor István, Török Ádám: Járműveken megkötött szén-dioxid gazdasági és környezeti hatásának elemzése,KLÍMA 21 FÜZETEK 60 pp. 56-61.

- Zádor István, Török Ádám: Buszok és haszongépjárművek gázüzeműre történő átalakításának gazdasági kérdéseiCAMION TRUCK & BUS 3 pp. 65-65.

- Zádor István, Török Ádám: Városi közlekedésben résztvevő buszok környezetbarátabbá történő átalakításának gazdasági kérdései,VÁROSI KÖZLEKEDÉS 2 pp. 92-96.

- Zádor István – Dr. Vajda István: Állandó mágneses szinkron csőmotor / generátor fejlesztése gépjármű lengéscsillapítókban, Elektrotechnika folyóirat, 2009 november, oldal: 10-13.

- A.G. Mamalis, A.Szalay, T.Rath: Preparation of metal/metal and metal/ceramic component parts by explosive compaction,5th EFEE World Conference 26-28 April 2009, Budapest, Hungary.

- A. Szalay, A.G. Mamalis, T. Ráth: Design and infrastructure of the special laboratory serving for development of explosive metalworking technologies, 5th EFEE World Conference 26-28 April 2009, Budapest, Hungary.

- Istvan Zador – Denes Kiraly – Dr Istvan Vajda: Synchronous tube machine optimization for vehicle shock absorber using permanent or superconducting magnets, ASC konferencia, Chicago, USA, 2008.08.17.

- A. Szalay, D. Horvath, A. Kladas, A.G. Mamalis: Magnetizing equipment for producing superconducting permanent magnets of High Temperature Superconducting bulks, 13th CEFC Conference, 11-15 May 2008, Athens, Greece.

- Istvan Zador – Daniel Horvath – Dr Istvan Vajda: PM synchronous tube machine optimization for vehicle shock-absorber, CEFC konferencia, Athen, Greece, 2008.05.10.

- Istvan Zador – Thomas Naber: Elektromagnetische Komponente für

Federung und Dämpfung im Fahrzeug, Fahrwerk vertikaldynamik Konferencia, Essen 2007. 11. 13-14.

- 4th International Working Conference on Total Quality Management – Advanced and Intelligent Approaches 27-30 May 2007, Belgrade, Serbia

- Istvan Zador – Istvan Vajda: Development of a permanent magnetic semi-active shock-absorber, International Review of Electrical Engineering, 2007. 08.

- A. Szalay, D. Horvath, I. Vajda, A.G. Mamalis and C. Harnois: Influence of some metallic additives on the flux trapping ability of High Temperature Superconducting Ceramics, Journal of Materials Processing Technology 181 (2007) 36-39.

- Zádor István – Dr. Vajda István: Állandó mágneses illetve szupravezetős fél-aktív járműlengéscsillapító tervezése, Tavaszi szél Konferencia 2007 május 17-19 Budapest, 147-152 old., ISBN 978-963-87569-1-6.

- J.G. Noudem, S. Meslin, D. Horvath, C. Harnois, D. Chateigner, B. Ouladdiaf, S. Eve, M. Gomina, X. Chaud, M. Murakami: Infiltration and Top Seed Growth-Textured YBCO Bulks With Multiple Holes,Journal of the American Ceramic Society, 90 [9] 2784-2790 (2007).

- Zádor István – László Dr. Palkovics: SEMI ACTIVE OR ACTIVE MAGNETIC SHOCK-ABSORBER WITH ENERGY RECUPERATIVE FEATURE, 11st World Automotive Congress (EAEC), Budapest, 2007.04.30. – 05. 02. ISBN: 9789638724458.

- ZÁDOR István, GIANONE László, NEUMAIER Andrea:Angle of rotation sensor, Németországi szabadalom (Knorr-Bremse), WO 2007/045427 A1, 2007. 04. 26.

- A.G. Mamalis, A. Szalay, N. Göbl, S. Marinel, I. Kotsis, M. Enisz, I.N. Vottea: Material and levitation characteristics of explosively compacted metal-sheathed YBCO discs.

- Á. Csanády, L. Ipacs, G. Kakuk, E. Kálmán, P. Nagy, K. Papp, I. E. Sajó, A. Szalay: Characterization and Comparison of Rapidly Solidified Al Particles Mechanically Milled Nanostructures and their Consolidated Structures Made by High Energy Rate Forming (HERF) Technique, Materials Science Forum, Volumes 537 – 538, pp. 321-328, February, 2007.

- Zádor István – Bence Falvy – László Dr. Palkovics: Electro-mechanical suspension actuator with energy recuperative feature, World Automotive Congress FISITA, Yokohama, 2006.10.22–25.

- Zádor István – Horváth Dániel – Dr. Vajda István: PM Tube machine designed for a controlled vehicle shock-absorber suited for energy recuperative operation, ICEM Konferencia, Kréta, Görögország 2006.09.02-2006.09.05, 333 old.

- S. Meslin, C. Harnois, C. Chubilleau, D. Horvath, D. Grossin, E.R. Suddhakar and J.G. Noudem: Effect of starting Y2BaCuO5 powder on transport properties of composite YBa2Cu3Oy / Y2BaCuO5 processed by infiltration and top seed growth’ Supercond. Sci. Technol. 19 (2006) s585-589.

- Zádor István – Horváth Dániel – Dr. Vajda István: Szinkron csőmotor, mint folyamatosan vezérelhető és energia visszatápláló lengéscsillapító, Tavaszi szél Konferencia 2006. május 4-8., Kaposvár, 344-347 old., ISBN 963 229 773 3.

- Zádor István – Falvy Bence – Horváth Dániel – Dr. Vajda István: Állandó mágneses lengéscsillapító tervezési lépései, Fiatal Műszakiak Tudományos Ülésszaka, 2006. március 24-25., Kolozsvár, 383-386 old., ISBN 973 – 8231 – 50 – 7.

- Á. Csanády, I. Sajó, J.L. Lábár, A. Szalay, K. Papp, G. Balaton and E. Kálmán: Al-Pb nanocomposites made by mechanical alloying and consolidation, Current Applied Physics Volume 6, Issue 2 February 2006, pages 131-134.

- C. Harnois, D. Grossin, D. Horvath, J. Noudem: Large multiseeded domains of (Y,RE)BaCuO obtained by the MUSLE technique,European Conference on Applied Superconductivity, Vienna, 2005.09.11-15.

- A. Szalay, G. Bertalan, I. Vajda, J. Kósa, M. Enisz: YBCO bulks for preparation of permanent magnets, J. of European Ceramic Society 25 (2005) 2931-2934

- Á. Csanady, I. Sajó, J. Labar, A. Szalay, K. Papp, G. Balaton, E. Kalman: Mechanically milled Al-Pb Nanocomposites consolidated by HERF Technique, 2nd International Conference on Nanomaterials and Nanotechnologies, 14-18 June 2005, Crete, Greece

- Zádor István – Falvy Bence: Linear Synchron Rohr Motor als kontinuierlich steuerte Stossdämpfer, 17. Frühlingsakademie und Experttagungen, Balatonfüred 2005.05.04-08, 145-148 old., ISBN 963 86697 3X.

- A.G. Mamalis, I.N. Vottea, D.E. Manolakos, A. Szalay, F. Marquis : Explosive compaction/cladding of YBCO discs: a numerical approach,Journal of Materials Processing Technology 161 (2005) 36-41.

- Zádor István – Farkas László: Aktív és passzív vasúti mágneses lebegtetések különleges megoldásai. 2. rész.,Elektrotechnika folyóirat, 2004. június, 179-181. old.

- Zádor István – Farkas László: Aktív és passzív vasúti mágneses lebegtetések különleges megoldásai. 1. rész.,Elektrotechnika folyóirat, 2004. május, 156-159. old.

- A. Szalay, A.G. Mamalis, M.Enisz, I. Vajda, D. Pandya and S. Khasyap: Fabrication of metal-sheathed HTS bulks of YBCO grains by explosive compaction, Proceedings of the 3rd Japanese-Mediterranen Workshop on Applied Electromagnetic Engineering, NTUA, Athens, May 19-21, 2003.

- A. Szalay, I. Vajda, N. Göbl, T. Porjesz: Dynamic Compaction of HTSC Powders And Granulates, In: Chubraeva, L. I. (ed), Development of High-Temperature Superconducting Alternators Combining Rotating and Levitating Principles, Russian Academy of Sciences, Division for Basic Researchers in Electric Power Engineering, Saint Petersburg, Russia, ISBN 5-901786-03-3, pp. 66-80, 2002.

- I. Vajda, A. Szalay, T. Porjesz, J. Lukács, N. Göbl: Development of HTS Rotating Electrical Machines, In: L. I. Chubraeva,. (ed), Development of High-Temperature Superconducting Alternators Combining Rotating and Levitating Principles, Russian Academy of Sciences, Division for Basic Researchers in Electric Power Engineering, Saint Petersburg, Russia, ISBN 5-901786-03-3, pp. 89-104, 2002.

- I. Vajda, S. Semperger, T. Porjesz, V. Sokolovsky, V. Meerovich, A. Szalay, W. Gawalek: Three Phase Inductive Fault Current Limiter for the Protection of a 12 kVA Synchronous Generator, IEEE Trans App. Sup, 11, No. 1 2515-8 (2001).

- S.M. Elaskari, A. Szalay, B. Palotás: A robbantásos hegesztés alkalmazása korrózióálló acélcsöveknél,Nemzetközi Hegesztési Konferencia, Budapest, 2000. június 6-9.

- S.M. Elaskari, A. Szalay, B. Palotás: A robbantásos hegesztés alkalmazása korrózióálló acélcsöveknél,Nemzetközi Hegesztési Konferencia, Budapest, 2000. június 6-9.

- A. Szalay, A.G. Mamalis, B. Raveau, G. Desgardin, I. Vajda, N. Göbl, T. Porjesz, L. Chubraeva, I. Kotsis: Dynamic compaction for fabrication of HTS ceramic components,“Fourth European Conference on Applied Superconductivity, 99”, Sitges, Spain, 1999 in Applied Superconductivity 99, Inst. Phys. Conf. Ser. 167, Ed. X. Obradors, F. Sandiumenge, and J. Fontcuberta, IOP Publishing Ltd, 963-966, 2000.

- A.G. Mamalis, D.I. Manolakos, A. Szalay, G. Pantazopoulos: Processing of High-Temperature Superconductors at High Strain Rates, Technomic Publishing Company Inc., Lancaster. USA. ISBN No.: 1-56676-878-0, 2000.

- A.G. Mamalis, D.I. Manolakos, A. Szalay, G. Pantazopoulos: Processing of High-Temperature Superconductors at High Strain Rates, Technomic Publishing Company Inc., Lancaster. USA. ISBN No.: 1-56676-878-0, 2000.

- I. Vajda, S. Semperger, T. Porjesz, A. Szalay, V. Meerovich, V. Sokolovsky: Three Phase Inductive Current Limiter for the Protection of a 12 kVA Synchronous Generator, IEEE Trans. on Appl. Supercond., 2000 (in print).

- T. Porjesz, I. Vajda, A. Gyore, A. Szalay, V. Sokolovsky, V. Meerovich, W. Gawalek: Operational Effects of Pulsating and Rotating Magnetic Fields in Energy Storage HTS Flywheels, IEEE Trans. on Appl. Supercond., 2000 (in print).

- I. Vajda, T. Porjesz, A. Györe, A. Szalay, and W. Gawalek: Upgrading Power Quality by Superconducting Flwyheels, Physica C, 341-348, 2609-10 (2000)

- V. Sokolovsky, V. Meerovich, I. Vajda, T. Porjesz, A. Szalay: Operation of an HTS Fault Current Limiter in an Asymmetrical Three Phase System, “Fourth European Conference on Applied Superconductivity, 99”, Sitges, Spain, 1999, in Applied Superconductivity 99, Inst. Phys. Conf. Ser. 167, Ed. X. Obradors, F. Sandiumenge, and J. Fontcuberta, IOP Publishing Ltd, 963-966, 2000.

- A. Szalay, A.G. Mamalis, B. Raveau, G. Desgardin, I. Vajda, N. Göbl, T. Porjesz, L. Chubraeva, I. Kotsis: Dynamic compaction for fabrication of HTS ceramic components,“Fourth European Conference on Applied Superconductivity, 99”, Sitges, Spain, 1999 in Applied Superconductivity 99, Inst. Phys. Conf. Ser. 167, Ed. X. Obradors, F. Sandiumenge, and J. Fontcuberta, IOP Publishing Ltd, 963-966, 2000.

- I. Vajda, S. Semperger, T. Porjesz, V. Sokolovsky, V. Meerovich, A. Szalay: One-Phase Fault Operation of an HTS Fault Current Limiter in a Three Phase System, Proceedings of 6th Joint Japan-Hungary Seminar on Applied Electromagnetics in Materials and Computational Technology, 1-3 November 1999, IOS Press, (in print).

- I. Vajda, A. Szalay, N. Gobl, V. Meerovich, V. Sokolovsky: Requirements for the Industrial Application of Superconducting Rotating Electrical Machines, IEEE Trans. on Appl. Supercond. 9, 1225-1228 (1999).

- I. Vajda, A. Szalay, N. Gobl, V. Meerovich, V. Sokolovsky: Requirements for the industrial application of superconductingrotating electrical machines, Applied Superconductivity, IEEE Transactions, Volume 9, Issue 2, Jun 1999 Page(s): 1225 – 1228.

- I. Vajda, S. Semperger, I. Városi, A. Szalay and N. Göbl: Design and Construction of an Experimental HTSC Rotating Machine with Permanent Excitation. In: L. Liaghzen, sh. Guoliao and Y. Luguang (eds.), MT-15 Proceedings, Part One, pp. 510-513., Beijing: Science Press (1998).

- N. Göbl, A. Szalay: Working Process for Superconductors by means of HERF-Technique, J. Phys.IV FRANCE 7 (1997) pp. 339-344.

- A.G. Mamalis, A. Szalay, N. Göbl, I. Vajda and B. Raveau: Near Net-Shape Manufacturing of Metal Sheathed Superconductors by High Energy Forming Techniques. In: Int. Workshop on the Processing and Applications of Superconducting (Re)BCO Large Grain Materials (Cambridge, 7-9 July 1997), to be published.

- I. Vajda, A. Szalay, N. Göbl, S. Semperger and I. Városi: Design Principles of a High-temperature Superconducting Electrical Machine. In: I. Vajda and A. Szalay (eds.), Proceedings of the 2nd Workshop on the Applied High Tc research and Education, pp. 1-6. Dept. Of Electrical Machines and Drives, TU Budapest, Organizing Committee (1997).

- V. Meerovich, V. Sokolovsky, I. Vajda, A. Szalay, N. Gobl: Design of Inductive HTSC Current Limiters Applied in Distribution Networks, Proc. of “2nd Workshop on Applied High-Tc Superconductivity: Research and Education”, Hungary, 1997, pp. 7-17.

- A.G. Mamalis, A. Szalay, N. Göbl, I. Vajda and B. Raveau: Near Net-Shape Manufacturing of Metal Sheathed Superconductors by High Energy Forming Techniques. In: Int. Workshop on the Processing and Applications of Superconducting (Re)BCO Large Grain Materials (Cambridge, 7-9 July 1997), to be published.

- V. Meerovich, V. Sokolovsky, S. Goren, G. Jung, I. Vajda, A. Szalay, N. Gobl: Application of Inductive HTS Current Limiters in Distribution Networks, Proc. EUCAS’97, in Applied Superconductivity 1997, Inst.of Physics Conf. Ser. 158, pp. 1227-1230.

- A.G. Mamalis, I. Vajda, A. Szalay, I. Kotsis, G. Pantazopoulos: Some small-scale high-temperature superconducting models for applications in electricity and transportation, Superlattices and microstructures 1997, vol. 21, pp. 251-255 ISSN 0749-6036.

- I. Vajda, A. Szalay, J. Lukács, I. Kotsis and N. Göbl: Recent Development on Power Engineering Applications of HTS Materials in Hungary. In: I. Vajda and A. Szalay (eds.), Proceedings of the 2nd Workshop on the Applied High Tc research and Education, pp. 1-6. Dept. Of Electrical Machines and Drives, TU Budapest, Organizing Committee (1997).

- N. Göbl, A. Szalay: Working Process for Superconductors by means of HERF-Technique, J. Phys.IV FRANCE 7 (1997) pp. 339-344.

- I. Vajda, A. Szalay, N. Göbl, S. Semperger and I. Városi: Design Principles of a High-temperature Superconducting Electrical Machine. In: I. Vajda and A. Szalay (eds.), Proceedings of the 2nd Workshop on the Applied High Tc research and Education, pp. 1-6. Dept. Of Electrical Machines and Drives, TU Budapest, Organizing Committee (1997).

- A.G. Mamalis, I. Vajda, A. Szalay, I. Kotsis and G. Pantazopoulos: Some Small-scale High-temperature Superconducting Models for Applications in Electricity and Transportation, Superlatt. Microstruct., 21 (Suppl.A), 251. 1997.

- V. Meerovich, V. Sokolovsky, I. Vajda, A. Szalay, N. Gobl: Design of Inductive HTSC Current Limiters Applied in Distribution Networks, Proc. of “2nd Workshop on Applied High-Tc Superconductivity: Research and Education”, Hungary, 1997, pp. 7-17.

- V. Meerovich, V. Sokolovsky, S. Goren, G. Jung, I. Vajda, A. Szalay, N. Gobl: Application of Inductive HTS Current Limiters in Distribution Networks, Proc. EUCAS’97, in Applied Superconductivity 1997, Inst.of Physics Conf. Ser. 158, pp. 1227-1230.

- A.G. Mamalis, I. Kotsis, G. Pantazopoulos, M. Enisz, A. Szalay and D.E. Manolakos:Effect of Heat-treatment on Explosively Compacted (Y-Ba-K-Cu-O) Superconductive Powders, Physica C, 280, 289. 1997.

- N. Göbl, A. Szalay: Working Process for Superconductors by means of HERF-Technique, J. Phys.IV FRANCE 7 (1997) pp. 339-344.

- I. Vajda, A. Szalay, N. Göbl, S. Semperger and I. Városi:Design Principles of a High-temperature Superconducting Electrical Machine. In: I. Vajda and A. Szalay (eds.), Proceedings of the 2nd Workshop on the Applied High Tc research and Education, pp. 1-6. Dept. Of Electrical Machines and Drives, TU Budapest, Organizing Committee (1997).

- V. Meerovich, V. Sokolovsky, I. Vajda, A. Szalay, N. Gobl: Design of Inductive HTSC Current Limiters Applied in Distribution Networks, Proc. of “2nd Workshop on Applied High-Tc Superconductivity: Research and Education”, Hungary, 1997, pp. 7-17.

- V. Meerovich, V. Sokolovsky, S. Goren, G. Jung, I. Vajda, A. Szalay, N. Gobl: Application of Inductive HTS Current Limiters in Distribution Networks, Proc. EUCAS’97, in Applied Superconductivity 1997, Inst.of Physics Conf. Ser. 158, pp. 1227-1230.

- A.G. Mamalis, G. Pantazopoulos, A. Szalay, I. Kotsis, I. Vajda and D.E. Manolakos:Multiple-pass Warm Extrusion of Explosively Compacted Ceramic Superconductive (Y-Ba-K-Cu-O)/metall Billets, Appl. Supercond. 4. 213. 1996.

- A. Szalay, I. Vajda, A.G. Mamalis, I. Kotsis, J. Bánkuti, N. Göbl and B. Palotás: A Novel Metal-ceramic Monolith: Silver Sheatheted Bulk High -Tc Superconductor with Silver Contacts. In. M. Uesaka, T. Mitani, I. Bársony and I. Vajda (eds.), Proc. 2nd Japan-Central Europe Joint Workshop on Modelling of Materials and Combustion, pp. 155-158. Technical University of Budapest, Program Committee (1996).

- A.G. Mamalis, I. Vajda, L. Mohácsi, I. Kotsis and A. Szalay: From Fabrication to Application: Ceramic Superconductors for Use in Magnetically Levitated Bearings. In: A. Barone, D. foriani and A. Tampieri (eds.), Fourth Euro-Ceramics, vol. 7. Part II, pp. 167-174. Faenza: Gruppo Editorale Faenza Editrice (l995).

- A.G. Mamalis, A. Szalay, D. I. Pantelis, G. Pantazopoulos, I. Kotsis, M. Enisz: Excimer laser surface treatment of high-Tc superconductive ceramic layered plasma-sprayed silver plates, Supercond. Sci. Technol. 8 (1995) pp. 470-475.

- A.G. Mamalis, N.M. Vaxevanidis, J. Prohászka, A. Szalay: On the manufacturing of Ag-CdO/Cu bimetallics by explosive cladding and rolling, Int. J. of Materials and Product Technology, Vol.9, Nos 4/5/6, pp. 334-353, 1994.

Company data

KOGÁT-Environmental Protection, Oil and Gas Technologies Research and Development Public Benefit Nonprofit Limited Liability Company

Founded: 17.11.2008.

- Headquarters: Zay str. 3. Budapest, H-1037

- Location: 5126 Jászfényszaru, Herman Ottó u. 2.

- Tax number: 14542264-2-4

- Community tax number: HU14542264

- TEÁOR: Other scientific and technical research and development

- PIC number: 883375412

Our contacts

Our contacts

Location / Billing address:

Herman Ottó str. 2. Jászfényszaru H-5126

Mailing address:

Kogát Közhasznú Nonprofit Kft.

1037 Budapest, Zay u .3